Improving customer service level for an aeronautical logistics flow

-

SectorLogistics subcontracting for the aeronautics industry

-

Size of entityThe scope of work included around 50 people, the client being one of the world's leading logistics companies.

-

Challenges of the missionIntegrate into a relationship where the end customer had lost confidence in our customer

Client context

The end customer manufactures and repairs aircraft parts and various sub-assemblies. They have subcontracted the logistics involved in the repair: the airlines send the parts to be repaired, the logistics subcontractor unpack and manage the administrative side (customs, invoice, BL, etc.), and deliver the repair workshop to the customer's premises (500 meters away). Once the repair is complete, the logistics subcontractor collects the part, packs it and ships it back to the customer.

This entire flow is subject to a contractual Lead Time of 12 days between the end customer and the airlines. The customer therefore asks his logistics provider to carry out the Import part in less than 4 hours, and the Export part in less than 12 hours.

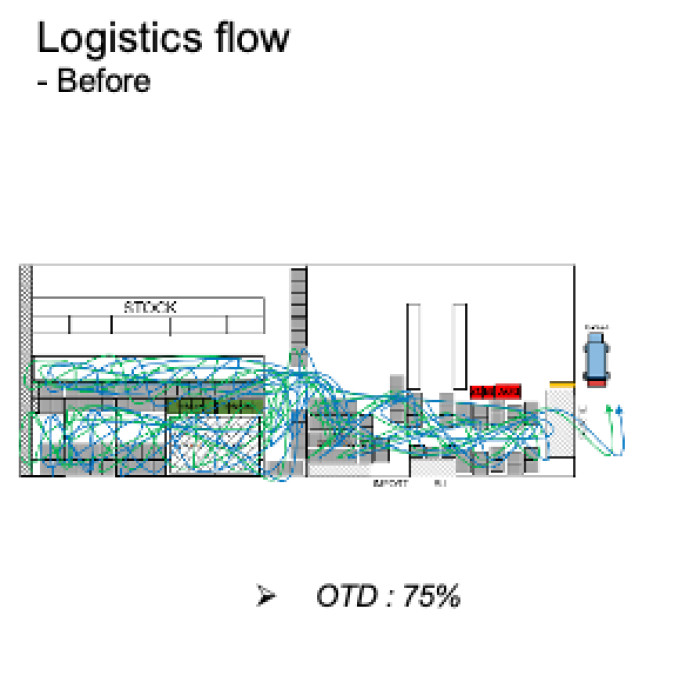

Our support to the logistics provider is driven by two challenges: to improve OTD (75% at the start of the project), and to reduce customer complaints.

Support put into place

We have identified three main lines of action to support our customer:

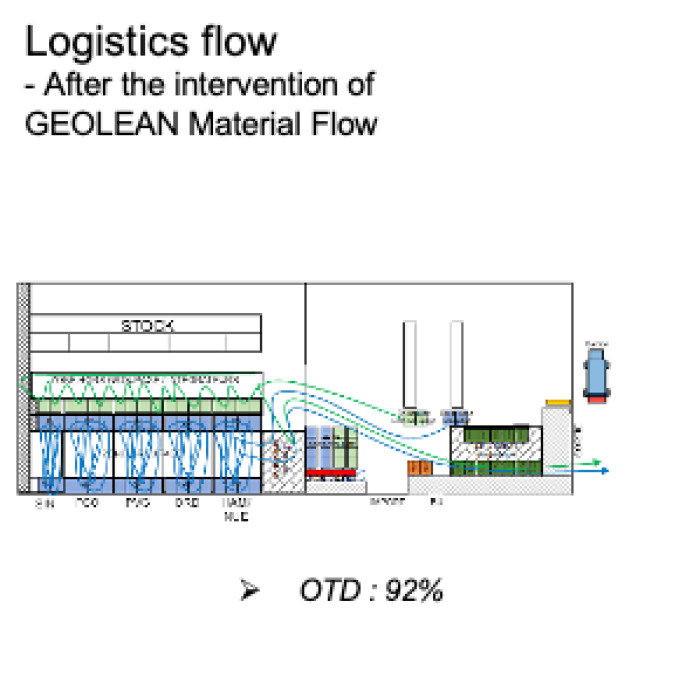

- Structuring workflow

- Improve the working environment for each task in the process

- Implement a results-oriented activity management system

As is often the case in the world of logistics with its short lead times, the challenge is to rapidly establish a flow of goods. That's what the first line is all about, highlighting the possible routes and sorting so that the parcel finds its way into the right pipe. This requires a physical set-up: sorting area, dedicated carts, queues, etc.

Once the flow is structured, i.e. the different channels are identified and physically in place, it's time to work on improving the comfort and ergonomics of each task, making sure that the customer's needs are met, that we're doing what's necessary, etc.

Last but not least, we need to set up a visual management system to make it easier to monitor activity, and to visualize any hazards or risks of delay. The idea is to force the team's shared understanding towards a common result: the zone must be empty within 4 hours.

The manager has a key role to play in this organization: reacting to unforeseen events, ensuring that the team runs smoothly, and managing flexibility because volumes are variable.

-

Length of the mission7 months

-

GEOLEAN Team (FTE)3 persons

-

P&L earningsBy improving performance, our customer was able to retain its end customer

Results

- Customer complaints: 56% reduction

- Delay claims: 65% reduction

- OTD: 75% => 92